I had to do a Fred Transplant last week. A grey fuzzy mold had taken up residence in on the sides of the jar above Fred’s liquid culture, so I set up a fresh container with fresh water and flour, and dipped a spoon down the center of Fred to the bottom, pulling up just a tiny amount of the stuff in there. Then I mixed it into the fresh stuff and covered it with plastic wrap (instead of a paper towel this time.)

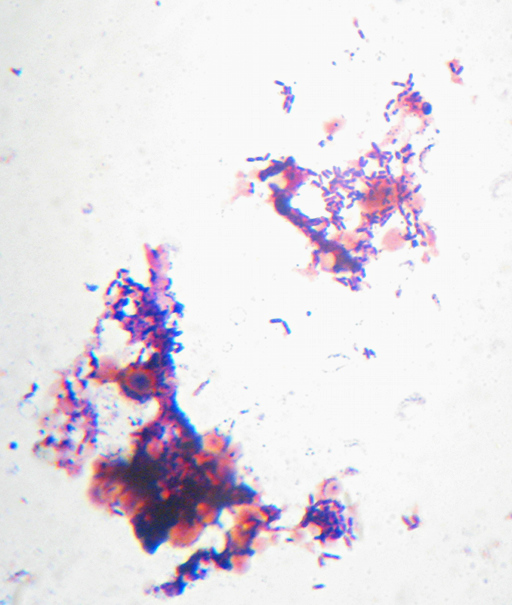

Fred smells like Swiss Cheese Feet right now, but he’s obviously still growing, as you can see from last night’s “Gram Stain” microscopy. The slightly blurry light-red-brown lumps are, I believe, yeast cells, possibly Saccharomyces boulardii, since I dumped a capsule of supposedly-still-viable “probiotic” yeast of that species into Fred previously. I have no idea who the bacteria are in here at the moment. I did also see a small number of longer, thinner bacterial cells in there (presumably Lactobacillus) though most of them are the ones you see here.

Meanwhile, I’m about to dig out the still-unused Hillbilly Autoclave and try it out on the media I’m mixing up to try to obtain a culture of genuine wild “native flora” vinegar/kombucha yeast-and-bacteria to play with from the local wildflowers that are just now getting into full bloom.

My starting recipe goes something like this: I mix up about 2 Liters of distilled water with about 100g of glucose (“Dextrose”/”Corn Sugar”), 100g of sucrose, 500mg of L-Arginine, and enough phosphoric acid to drop the pH down to about 5.5 to 6.0. That is intended to be then poured into small “canning” jars in about 100ml amounts and pressure-cooked for at least 15 minutes to sufficiently sterilize and seal them. Meanwhile, a single generic-brand children’s chewable vitamin is crushed up and dumped into a 4-oz bottle of cheap vodka and well shaken.

Then when it comes time to go bioprospecting, I’ll pop open the jar of acidic sugar solution and add about 5ml of the cheap-vitamin-vodka to it to give me about 2% ethanol, and then go find some flowers to cut off and dump into the jars, which will be loosely covered with foil (to let air in but keep dust out) and put in a nice quiet cupboard to grow for a few days.

Hypothetically, the only things that are likely to grow in that will be microorganisms associated with vinegar-making. At some point I’ll also make up a batch of sweet black tea and see if I get a kombucha-like culture going in it, and make up some solid media to try to isolate individual microbes from it.